01

Minimal employment

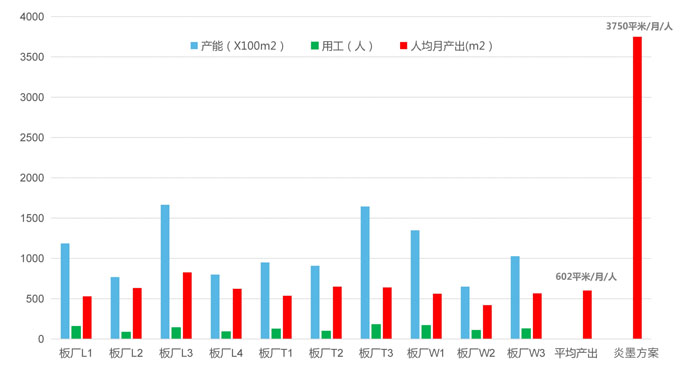

Survey of the industry's ten PCB factories at present, the average level of soldering & text process per capita monthly output value of 602㎡

Our aims to increase monthly output per capita to 3,750㎡ by significantly increasing equipment capacity and reducing the number of laborers

02

Lowest cost

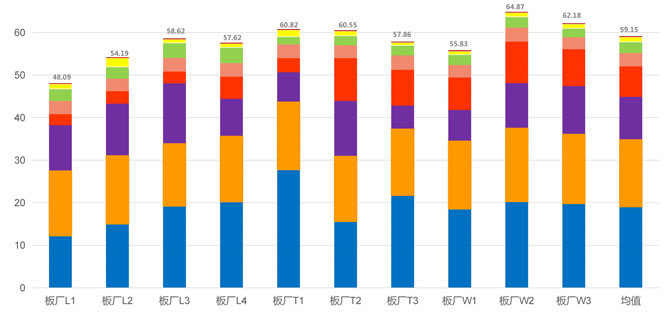

According to the survey of ten PCB factories in the industry at present, the average cost of the welding resistance & text process is 59.15 yuan /㎡

We customizes exclusive solutions for customers, bears all hardware inputs alone, and promises customers a greater than 5% reduction in solder mask and text costs

03

Highest efficiency

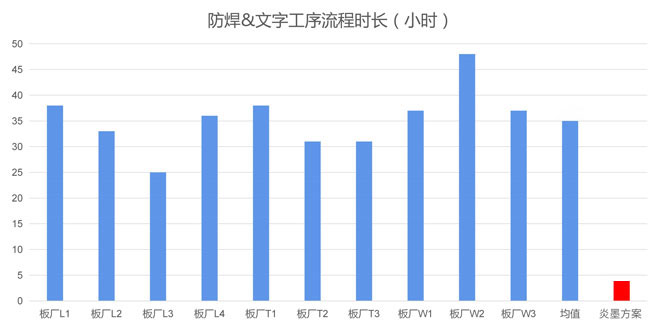

A survey of ten PCB factories showed that the average process time of solder & text was 35 hours

Our target is pre-treatment of solder mask to text after baking out the board time is only 4 hours

04

Excellent quality

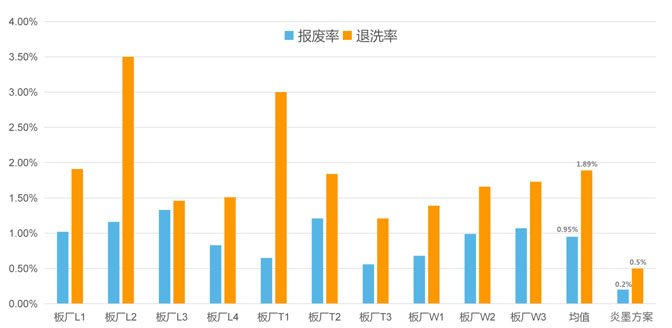

According to the survey of ten PCB factories in the industry, the average scrap rate of welding prevention and writing process is 0.95% and the wash rate is 1.89%

Our target is solder mask and text scrap rate 0.2%, rewash rate 0.5%

05

Quality First

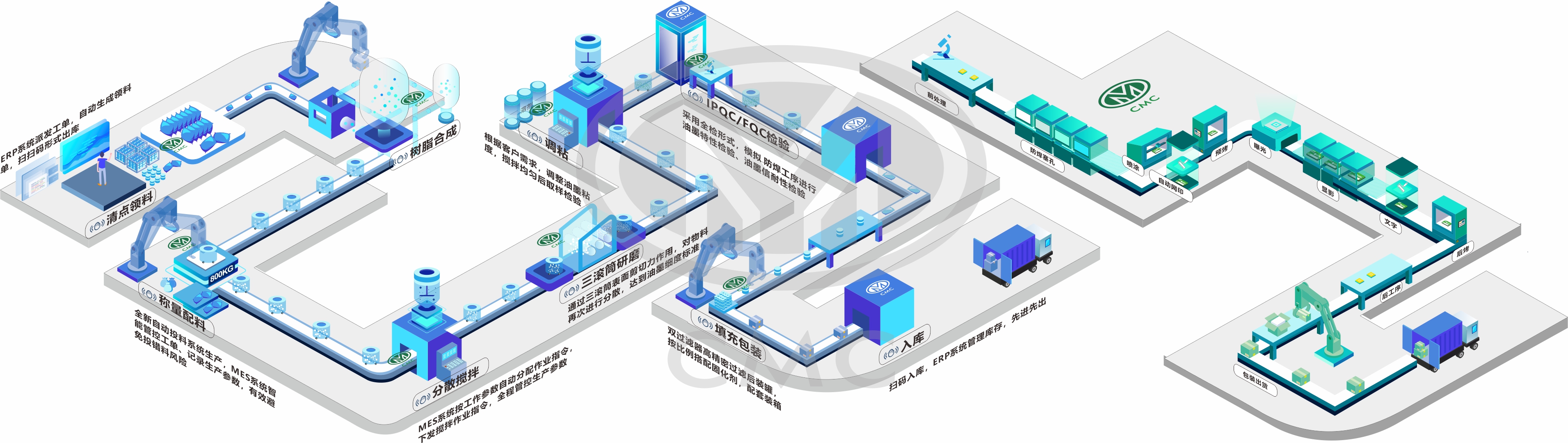

Talent specialization, equipment talent specialization, process management specialization, DI exposure machine high-end equipment, fully automatic coating line, excellent operability, super high sensitivity, excellent functionality

06

Energy saving

VOC emission is reduced by 30%, energy saving by 50%, packaging material by 50%, hazardous waste by 90%, manpower by 75% and materials by 20%